CNC machining is a manufacturing technique that uses high-speed cutting tools to produce precise parts from metal, plastic, or other materials. CNC machining is often used for prototyping because it can produce parts with tight tolerancing and eliminates the need for prototype tooling.

Rapid prototyping is a crucial step in the product design and development cycle. Product prototypes are helping understand the design, identify manufacturing defects and analyze the scope of failure in the product design cycle itself. It is essential to prevent defects and failure during the production cycle, or else they may lead to huge losses in terms of money and product recalls.

There are different types of prototypes manufactured in industries, such as dummy prototypes, functional prototypes, digital prototypes, etc. These prototypes can be produced using different techniques, however, their manufacturing times and costs largely vary. CNC machining is the most common technique used for rapid prototyping.

What Is CNC Prototyping?

CNC Machining Prototyping uses 3D CAD design as the input and fabricates the part through milling or computer control cutting. It helps you to prepare a model first to check out its efficiency, functional properties, and concerned problems before creating plenty of mock-ups or full mass production.

In addition, these machined prototypes are helpful for market and functional product tests, and they help check for defects and design errors to find out if the product fits the purpose of the design perfectly. As a result, design iterations can be easily made to improve the product’s functionality and customer satisfaction.

Various CNC Prototype Machining Operations

Various precision CNC prototyping processes help to get the best prototyping results. Here are common CNC machining operations:

CNC Milling

CNC milling is a subtractive process involving milling machines with multipoint cutting tools. These CNC machines cut materials from metal blocks and solid plastics to form prototypes with varying geometries according to design. Each cutting point rotates to make a sharp cut with varying lengths and shapes on the workpiece.

The tools make shallow cuts, broad cuts, or flat-bottom cavities to create the parts according to design when milling. The axes used by the machine depend on the prototype’s complexities, and the machine has additional axes that enhance its movement, allowing more precise cuts.

CNC Turning

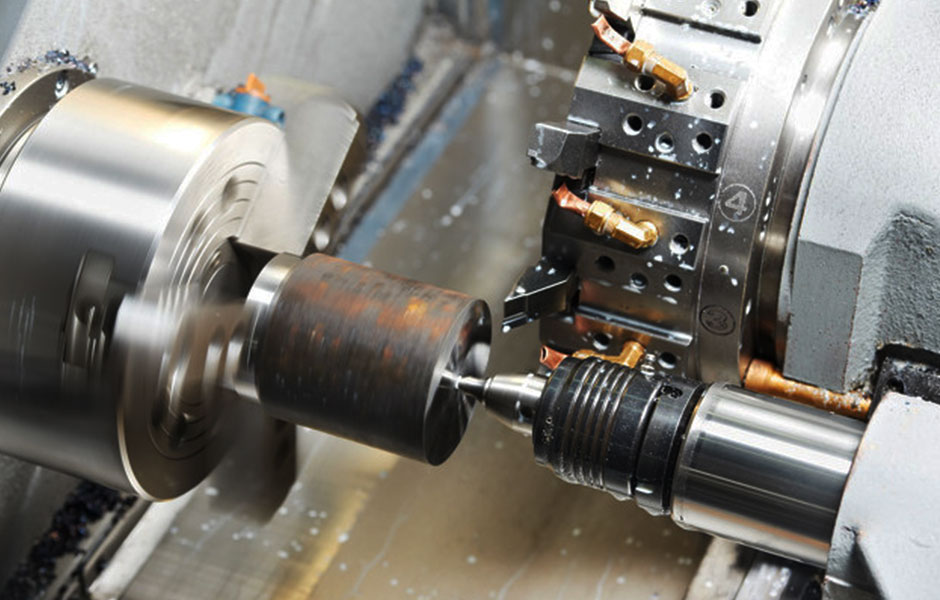

CNC turning is a prototyping process that involves using a lathe tool to form detailed prototypes and final products with cylindrical features. In this process, the workpiece rotates close to the stationed cutting tool instead of turning the cutting tool to remove excess material from the stock material.

The turning machine uses a single-point cutting tool to cut material from the bar stock creating cylindrical parts with a specified diameter. This process can machine linear features on the workpiece’s exterior and interior edges- tapers, slots, and threads.

Multi-axis Machining

CNC multi-axis machining is a versatile and practical prototyping process. There is an extensive list of CNC machining technologies, such as 4-axis, 5-axis, and up to 9-axis. These multiple axes enable the production of prototypes with complex specifications. In addition, the higher the number of axes a CNC machine, the higher its capability to machine difficult parts and provide high tolerance.

Benefits of Choosing CNC Machining for Rapid Prototyping:

- Digital to Physical Prototypes

In CNC prototyping, the digital image or stimulation of the prototype is created. Once the digital stimulation shows the appropriate function of the prototype, and then only it is manufactured. This helps ensure the prototypes are built according to specifications.

- Precise Tolerances

As the full name implies, Computer Numerical Control machining is controlled by a computer program. Essentially, the machine uses a CAD drawing file to create an item from a solid block of material. And while machines can sometimes break down or experience errors, they’re much more accurate than even the most skilled human operator.

As long as the machine is set up properly and the design files are correct, CNC machining can produce items with very tight tolerances. Some CNC machines are capable of tolerances as close as +0.05mm or 50 microns. This precision makes it easy to create prototypes exactly as you envision them, with intricate detail, multiple components, or any design features you need.

- Mimics Finished Product

Some prototypes are designed to simply mimic the appearance of the finished product, while others are designed to mimic its form as well as its function. When you choose CNC machining for rapid prototyping, the prototype will very closely resemble the finished product, including an appearance as well as functionality.

Depending on the design of your prototype, you can use CNC machining to construct a single finished piece, or multiple pieces to assemble the prototype. Other rapid prototyping processes, like 3D printing, often produce visual representations of the prototype or components. CNC machining, on the other hand, creates products very similar to those produced through injection molding, which is commonly used in mass production. Therefore, CNC machining produces durable, functional pieces that will very closely resemble the finished, sale-ready product.

- Many Different Materials are Available

While processes like 3D printing generally work with plastic polymers, CNC machining works with a wide variety of different materials. Aluminum and aluminum alloys are the most common materials used in CNC machining, however, there are many other materials available. CNC machines may also use brass and stainless steel, as well as non-metallics like plastics, wood, and foam. This makes it easy to construct a prototype with hardness, tensile strength, wear resistance, and other important characteristics.

- Easy to Change

Since CNC machining is controlled by a computer program and attached to a computer design file, it’s relatively easy to change and edit your prototype as you continue to improve and develop the design. In a full-production run using injection molding or similar processes, it’s very difficult and expensive to change the design. Choosing CNC machining for rapid prototyping allows you to continue to make improvements.

- Fast Turnaround

CNC machining is an efficient process that can give you hundreds of units in a very short time. Once the design files are perfected and the process is set up, the machines will work quickly and precisely. While 3D printing can take hours to produce a single unit, CNC machining can produce dozens or hundreds of units in the same time frame.

- Short Run

CNC machining can produce a few dozen or hundreds of thousands of units. If you have reached the stage in your prototype development where you are ready to test your product with your first users, CNC machining can quickly produce multiple usable, durable prototypes that closely mimic the final product.

- Finishing Options

With your parts constructed, there are also many finishing options to make it easy to get the look and feel you want for your prototype. This may be especially important if you are comparing the effects of different appearances on sales values such as a painted finish compared to a chrome finish. Or you may wish to ensure that a particular finish performs the way you expect, such as a powder-coated part adequately resisting rust. Your prototype may be left as-is, or it may be powder-coated, sanded, chrome-plated, bead-blasted, anodized, and more.

Although CNC machining is a highly automated process, still CNC prototyping brings desired results only if performed by experts. The coding, material consideration, CAD design, and machine availability make it a task for experts.

CNC Machining Service

CNC Prototyping Shop is a CNC manufacturing and sheet metal fabrication company, including CNC machining services, CNC milling services, CNC turning services, laser cutting services, and stamping services.

CNC Prototyping Shop offers professional CNC machining and rapid prototyping service for making a wide array of product parts. Our excellent quality control systems ensure that all our deliveries are speedy and standard for every manufacturing size in both low-volume and high-volume productions.

Our engineers will help you to find the solution that fits your time, and budget to market, Please contact us today for a quote.