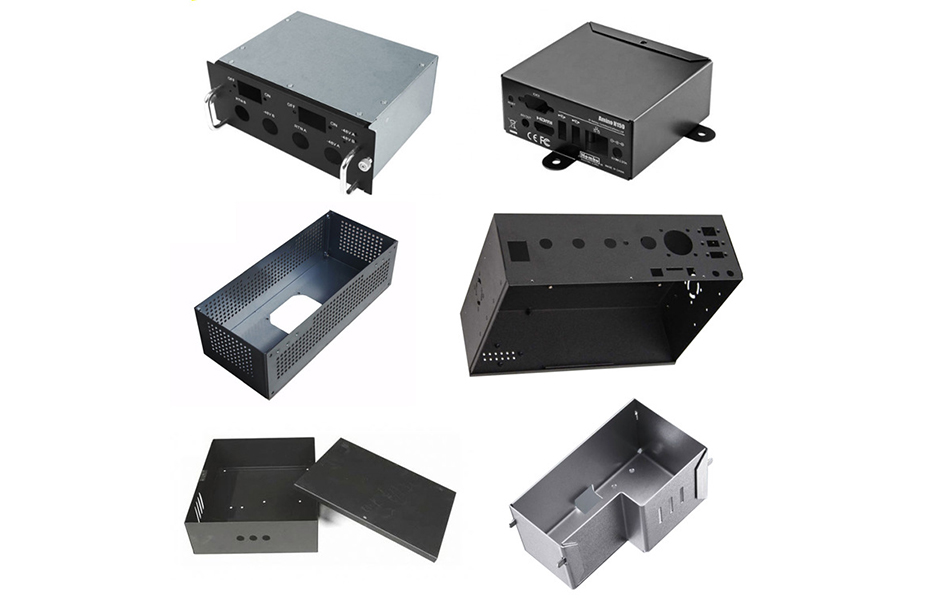

Overview of Sheet Metal Stamping

Sheet metal stamping is a manufacturing process in which flat sheets of metal are formed into desired shapes using a stamping press. The process involves placing a sheet of metal between a punch and die, and using a stamping press to apply force to the punch, which then cuts and shapes the metal into the desired form. Sheet metal stamping is commonly used in the automotive, aerospace, and appliance industries to produce a wide range of parts, including body panels, fuel tanks, and air ducts. The process is fast, accurate, and cost-effective, making it a popular choice for mass production of metal parts.

Manufacturing Process of Metal Stamping

Metal stamping is a cold-forming manufacturing process that includes extensive operations for changing flat metal sheets into distinctive shapes with features such as bends, holes, grooves, and slots. Determining which process is appropriate for a particular part is an essential step in the design process. Below are the most widespread metal stamping manufacturing processes:

Blanking

Blanking is a manufacturing process in which a piece of sheet metal is cut into a desired shape using a punch and die. The process involves placing a sheet of metal between a punch and die, and using a stamping press to apply force to the punch, which then cuts the metal into the desired shape. Blanking is commonly used in the automotive, aerospace, and appliance industries to produce a wide range of parts, including body panels, fuel tanks, and air ducts. The process is fast, accurate, and cost-effective, making it a popular choice for mass production of metal parts.

Piercing

Piercing is a manufacturing process in which a hole is cut or formed in a piece of sheet metal using a punch and die. The process involves placing a sheet of metal between a punch and die, and using a stamping press to apply force to the punch, which then cuts or forms the hole in the metal. Piercing is commonly used in the automotive, aerospace, and appliance industries to produce a wide range of parts, including body panels, fuel tanks, and air ducts. The process is fast, accurate, and cost-effective, making it a popular choice for mass production of metal parts. Unlike other cutting processes, such as sawing or laser cutting, piercing does not produce burrs or other deformations on the edges of the hole, which makes it a good choice for applications where a smooth, clean hole is desired.

Embossing

Embossing is a manufacturing process in which a design or pattern is raised or indented on a piece of sheet metal using a punch and die. The process involves placing a sheet of metal between a punch and die, and using a stamping press to apply force to the punch, which then presses the design or pattern into the metal. Embossing can be used to create a variety of designs and patterns on metal surfaces, including logos, text, and geometric shapes.

Bending

Bending is a manufacturing process in which a piece of sheet metal is bent into a desired shape using a punch and die. The process involves placing the sheet of metal between a punch and die, and using a stamping press to apply force to the punch, which then bends the metal into the desired shape. Bending can be used to create a variety of shapes, including straight bends, curved bends, and complex, three-dimensional shapes.

Materials

Sheet metal can be produced using a variety of metal materials, including steel, aluminum, brass, and stainless steel. The specific material used depends on the design, application, and performance requirements of the sheet metal part. For example, lightweight metals such as aluminum may be used for the production of lightweight automotive components, while stronger metals such as steel may be used for the production of heavy machinery parts. For applications requiring corrosion resistance, stainless steel may be used for the production of sheet metal parts.

Sheet metal stamping is a manufacturing process that neither subtracts nor adds material to the final parts. This process involves forming to create the desired shape from straight metal sheets. Metal sheets are bent on specialized equipment utilizing specific dies and punches. In most cases, sheet metal stamping does not require heating the sheet. Hence there is no heat distortion in the die surface. Metal stamping is both a cost-effective and environmentally benign process.

CNC Machining Service

CNC Prototyping Shop is a CNC manufacturing and sheet metal fabrication company, including CNC machining services, CNC milling services, CNC turning services, laser cutting services, and stamping services.

CNC Prototyping Shop offers professional CNC machining and rapid prototyping service for making a wide array of product parts. Our excellent quality control systems ensure that all our deliveries are speedy and standard for every manufacturing size in both low-volume and high-volume productions.

Our engineers will help you to find the solution that fits your time, and budget to market, Please contact us today for a quote.