Electrical discharge machining is a highly precise manufacturing process that uses electricity to remove materials from the workpiece instead of a cutting tool. In fact, the workpiece isn’t touched by a tool at all. Instead, a high-frequency electrical charge disintegrates the material molecule by molecule to make a sharp cut.

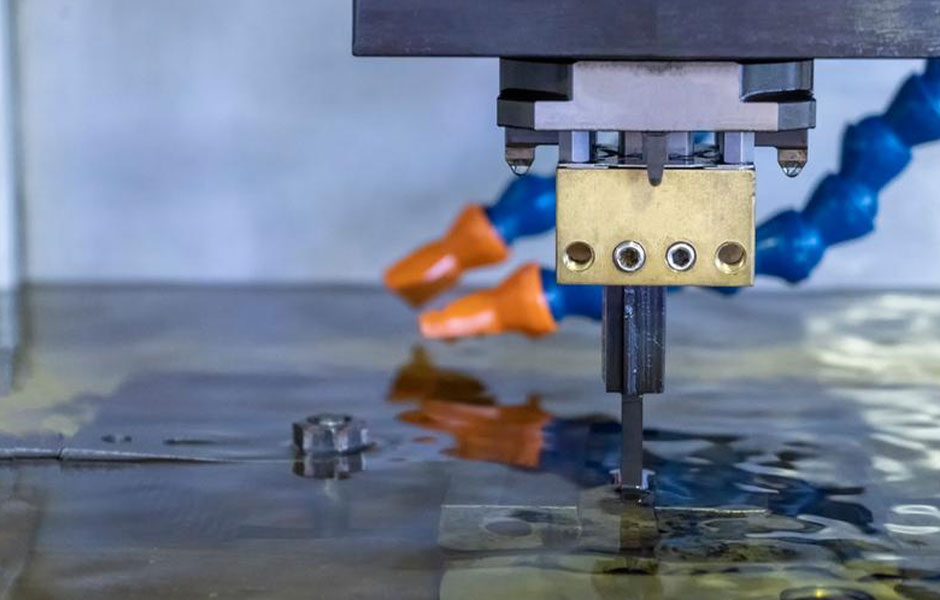

During the electrical discharge machining process, an electrode made of copper, brass, graphite, or tungsten is brought within a hair’s width of the electrically conductive workpiece to be machined. Then, the voltage between the electrode and the workpiece is increased until an electrical discharge, or spark occurs.

This process is repeated at high frequencies (on the order of 10KHz) and as the sparks fly between the electrode and the workpiece, tiny cuts are left behind on the material’s surface. To stop the electrical discharge and prevent the sparks from conducting between the electrode and the workpiece, the finished part is then submerged in a dielectric fluid.

In general, electrical discharge machining is best-suited for low-volume production runs of extremely precise parts. EDM is often used to make molds, coinage dies, jet engine turbines, and components for medical devices.

Types of Electrical Discharge Machining

The EDM process is unique and conventional. However, this does not mean that there is only one approach to this process. There are three different types of EDM. This helps to assure that there are alternative methods if one type does not fit adequately. The different types of electrical discharge machining include:

Wire EDM

Sometimes referred to as wire erosion or spark EDM, wire EDM is a popular process. It involves the use of a brass wire or thin copper to cut the workpiece. Here, the thin wire acts as the electrode. The dielectric liquid, in this case, is usually deionized water. During the process, there is the continuous unfurling of the wire from an automated feed using a spool.

This is because the electrical discharge may become compromised by the workpiece and the wire. Therefore, there is a need for a new discharge path in the cut. This approach works very well. However, engineers must note that the wire must pass through the workpiece completely. Hence, it essentially creates two-dimensional cuts in three-dimensional parts. You tend to get results that are similar to the traditional CNC machining processes.

Hole EDM

As the name implies, hold drilling EDM helps explicitly in fast hole drilling. The electrodes for hole EDM are tubular, enabling the dielectric fluid to flow through the electrodes easily.

Unlike the traditional drilling methods, hole EDM can machine very tiny and deep holes. Furthermore, these holes do not require any deburring. Regardless of the metal hardness or type, this process enables the effective drilling of precision holes faster than the conventional methods.

Sinker EDM

This is the conventional EDM, also referred to as Ram EDM, die sinking, or cavity-type EDM. Cavity type because it creates complex cavity shapes for various casting applications such as plastic injection molding.

This process uses pre-machined copper or graphite electrodes to form a “positive” of the required shape. Then, there is the pressing of the electrode into the workpiece to create a negative of the original material shape. Some factors may influence the choice of electrode material in sinker EDM. These include the electrode’s resistance to erosion and its conductivity, which is usually easier to machine graphite than copper material. However, copper is stronger and more conducive.

Advantages of Electrical Discharge Machining

There are several unique advantages associated with EDM manufacturing. Some of them include:

Work on Any Type of Electrically Conductive Material

When you think of EDM manufacturing, the first thing that will come to your mind is its ability to work on a wide range of materials. As long as your material is electrically conductive, EDM is always the right process. This makes it possible to machine parts that are difficult for traditional machining methods. These include parts made from titanium and tungsten carbide.

No Mechanical Force is Involved

Another crucial benefit is that no mechanical force is put into the workpiece. Therefore, you don’t have to worry about producing fragile outlines. This becomes easy because there is no need for high cutting force before removing the material. Since no contact occurs between the tool and the workpiece, there is no issue of mechanical stress.

Enables Various Shapes and Depths

With EDM, reaching shapes and depths seems impossible with a cutting tool. It is an effective method for deep processing with very high tool lengths and diameter ratios. You can easily cut sharp internal corners, narrow slots, and deep ribs with the EDM process.

Encourages Better Surface Finish

Manufacturers also argue that injection molding surface finish is often better with EDM than traditional methods. This may be true because the EDM process gives surfaces high precision and fine finishes.

Work on Hardened Material

Other conventional machining processes need to be done before hardening the workpiece. On the other hand, EDM works perfectly on hardened material. Therefore, it is easy to avoid any potential deformation from heat treatment.

EDM manufacturing, being a great part-production option, definitely has lots of advantages in creating high-precision parts with desired shapes. If you have complex parts to produce, consider the EDM process.

CNC Machining Service

CNC Prototyping Shop is a CNC manufacturing and sheet metal fabrication company, including CNC machining services, CNC milling services, CNC turning services, laser cutting services, and stamping services.

CNC Prototyping Shop offers professional CNC machining and rapid prototyping service for making a wide array of product parts. Our excellent quality control systems ensure that all our deliveries are speedy and standard for every manufacturing size in both low-volume and high-volume productions.

Our engineers will help you to find the solution that fits your time, and budget to market, Please contact us today for a quote.