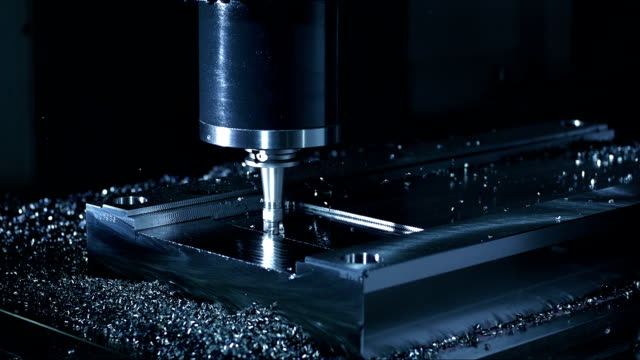

Manufacturing has seen a pronounced need for rapid prototyping. As industries strive for faster product development cycles, the demand for efficient and precise prototyping methods has skyrocketed. Enter CNC machining—a game-changer in the realm of rapid prototyping. In this article, we’ll delve into the numerous benefits of using CNC machining for rapid prototypes.

1. Precision and Accuracy

CNC machining stands out for its unparalleled precision. Computer-aided design (CAD) files guide the machinery, ensuring that each prototype mirrors the original design with high fidelity. This level of accuracy is crucial, especially when testing the functionality of a part or assembly.

2. Wide Range of Materials

Unlike some prototyping methods that are limited to specific materials, CNC machining can handle a vast array of materials, including metals, plastics, and composites. This flexibility allows manufacturers to create prototypes that closely resemble the final product in terms of material properties.

3. Speedy Turnaround

Time is of the essence in product development. CNC machines can operate 24/7 without human intervention. Once the design is loaded, prototypes can be produced quickly, allowing for faster iterations and quicker feedback loops.

4. Scalability

While CNC machining is excellent for producing one-off prototypes, it’s equally adept at creating small batches of parts. This scalability is beneficial for testing multiple variations of a design or for early-stage market testing.

5. Cost-Effective for Complex Designs

For intricate designs with complex geometries, CNC machining can be more cost-effective than other prototyping methods. There’s no need for expensive molds or tooling—just a one-time setup and the machine does the rest.

6. Post-Processing Opportunities

CNC-machined prototypes can undergo a range of post-processing treatments, such as painting, anodizing, or assembly. This capability allows manufacturers to produce prototypes that are not only functional but also aesthetically representative of the final product.

7. Sustainable and Waste-Reducing

CNC machining is a subtractive manufacturing process, meaning it carves out material to create the desired part. The leftover material can often be recycled or reused, making it a more sustainable option compared to additive manufacturing methods.

CNC machining has firmly established itself as a cornerstone in the rapid prototyping arena. Its precision, versatility, and speed are unmatched, providing manufacturers with tangible prototypes that drive informed decisions. As we continue to push the boundaries of innovation, CNC machining will undoubtedly play a pivotal role in bringing ideas to life.

About CNC Rapid

At CNC Rapid, we pride ourselves on being at the forefront of CNC machining services. Our commitment to quality, precision, and timely delivery has made us a trusted partner for businesses seeking top-notch CNC machined prototypes and products. With a team of dedicated professionals and state-of-the-art machinery, we ensure that your visions are transformed into tangible realities. Visit our website to learn more about how we can assist you in your next project.