For a long time, Plastic manufacturing has been the domain of mass production. You had to have an injection mold and the machine tool that injected plastic into the mold. The whole system was very expensive and any kind of changes in the design of such a system is very costly. This is why metal has been the number one prototyping material for a long time, especially since the rapid development of digital systems and consequently computer numerical control machines. However, that changed with the coming of rapid prototyping processes.

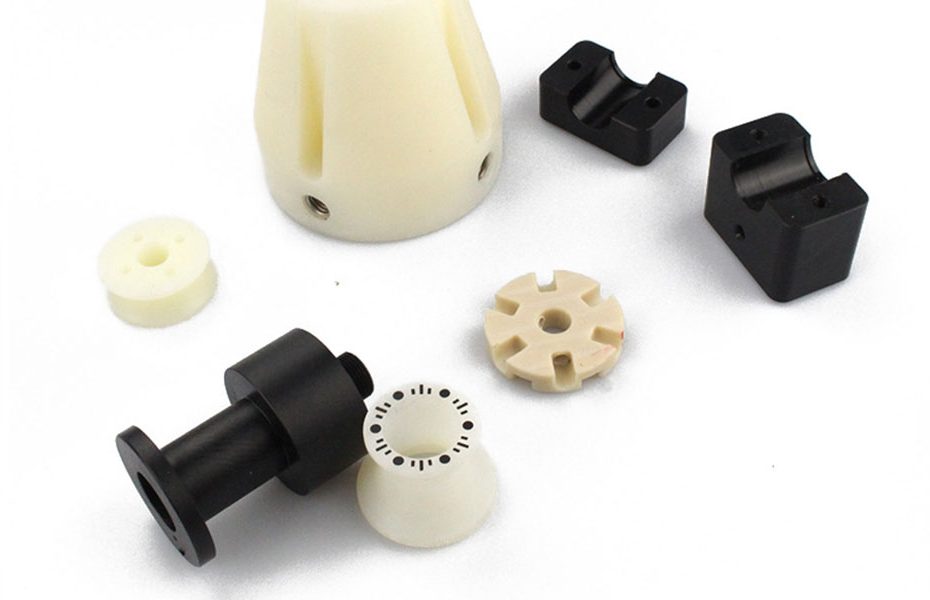

In nearly every industry, prototyping is a necessary stage of product development that ultimately determines whether or not your production efforts will be successful. And with the advent of rapid prototyping, it is now both affordable and easy to produce plastic prototypes quickly. CNC plastic prototypes utilize CNC machining to create functional prototypes that meet exact specifications, typically with fast turnaround times.

Difference Between CNC Plastic & Metal Machining

To begin with, “Can CNC machines cut plastics?”, for this question, the answer is obvious and yes, of course. Many people outside the rapid prototype manufacturing industry, when it comes to CNC machining, most of them will only associate with CNC metal. Even if they know that CNC can process plastic, fewer of them know the difference between metal machining and plastic machining.

First of all, plastic material has low hardness and low-temperature resistance compared with metals. Therefore, it is necessary to use appropriate tools and parameters according to different kinds of plastics. Different from metal, CNC plastic needs to slow down the processing speed, lift the cutter more often and have better cooling control to prevent the material from melting which could be caused by high temperature when under machining. Poor control will not only easy to process bad quality products but will also cause high damage to CNC tools.

In addition, the processing of plastic products has a thing to do with its material characteristics, and there will be stress from internal material. As a result, deformation and cracking could easily occur, which would eventually lead to out-of-tolerance or scrap products. To control this problem, the engineers should have more extensive processing experience to allow them to control every detail in the processing.

Last but not least, though there is much plastic for CNC machining, not all materials are suitable, For example, material with relatively low hardness is obviously too soft to be machined. In general, experienced prototype manufacturers are able to give some proper recommendations and provide the best manufacturing solutions according to the actual needs of customers.

Are CNC Plastic Prototypes Right for Your Project?

When developing your plastic prototype, your choice of manufacturing method will be determined by the volume of prototypes needed, the material, the type of testing they will undergo, and how complex or exact the prototype must be. CNC plastic prototypes offer numerous benefits to your product development:

Advanced Materials

3D plastic prototypes are often limited to less technical plastics. CNC machining can produce prototypes from the most advanced engineering plastics, such as PEEK, Vespel®, and Torlon®.

Complex Geometry

CNC machining can easily produce sophisticated niches and angles that can’t be achieved by 3D printing or injection molding.

Consistent Quality

Since CNC machines are computer controlled, you can be certain that each prototype will be identical to the last. And all our parts undergo a comprehensive, ISO 9001:2008 compliant quality inspection before shipping.

Cost Savings

Unlike injection molding, CNC plastic prototypes don’t have high tooling costs. They also don’t require postprocessing to meet design specifications like 3D printed prototypes, eliminating the need for costly secondary services.

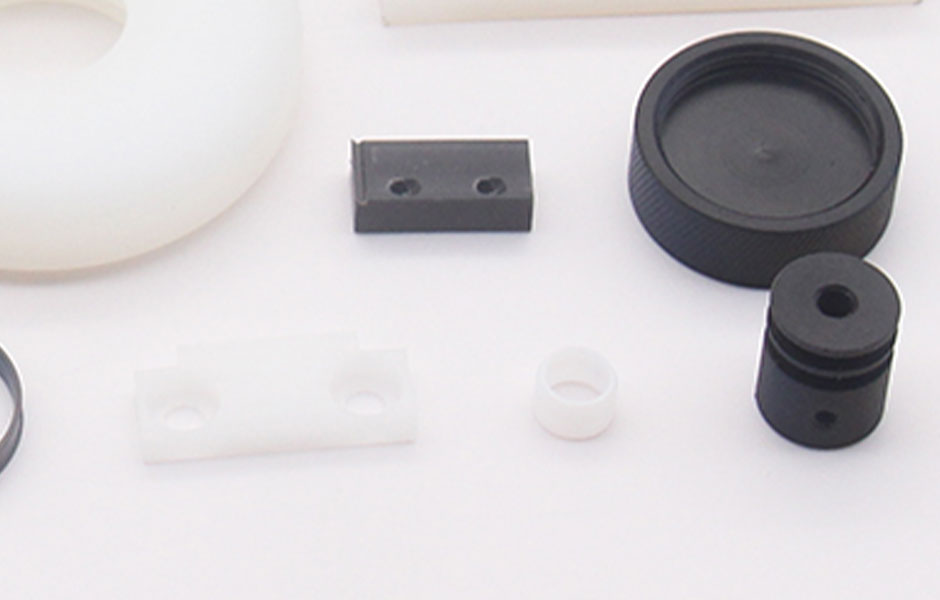

Superior Finishes

CNC plastic prototypes have a superior surface texture when compared with other processes, giving them a clean, smooth look. With our state-of-the-art CNC milling machines, we can achieve surface finishes as smooth as 15Ra.

Tight Tolerances

If tight tolerances are fundamental in end-use or testing your prototype, CNC machining is a must. We excel at tight tolerance machining, achieving tolerances of +/- .001.

Can Accommodate Any Production Volume

Whether you need ten plastic prototypes or 500, CNC machining can easily handle the volume. And while tooling for injection molds can take weeks to produce, CNC machines can start churning out parts as soon as your design is programmed into the machine.

Is CNC Machining Good for Prototyping?

Inarguably, 3D printing is considered the preferred option for plastic prototyping. However when functional prototypes are required then CNC machining still comes as the number one choice. The importance of CNC machining cannot be denied. Sometimes, CNC machining or milling can be an excellent option for metal and plastic prototyping. For example, it may be better to use CNC machining based on tolerance capabilities or material options available. Or it can also be decided based on required geometry, finishing, and appearance. But one thing is sure, the CNC machining method is cost-effective if we need 1 to 10 prototype pieces.

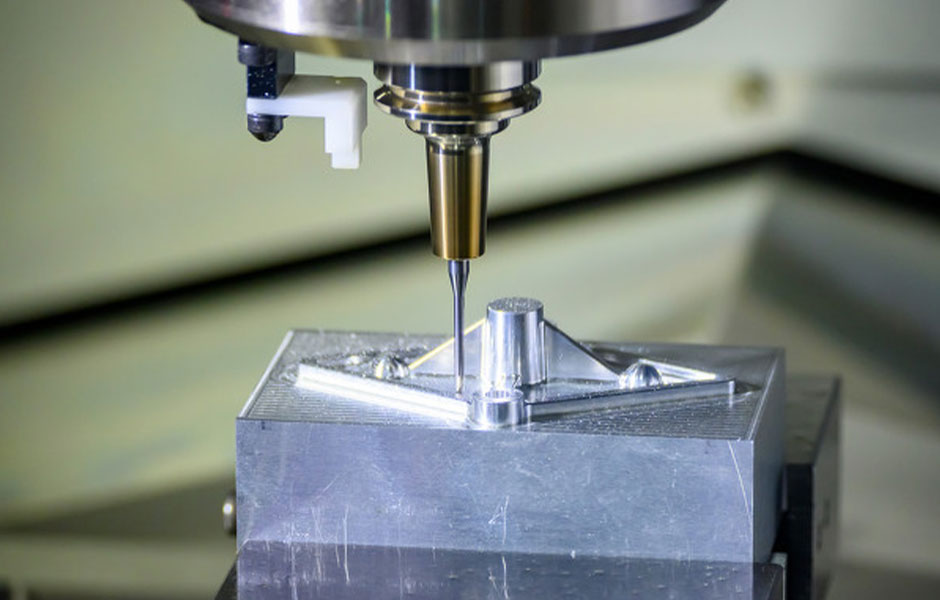

How to create a Metal and Plastic Prototype with CNC Machining?

Given the part’s geometry, CNC machining can be the most suitable and rapid method for creating metal and plastic prototypes. Usually, CNC machines produce 3D objects by removing excess material from the solid block, with the aid of cutting tools. The movement of these tools is precisely controlled by the series of cutter paths, generated directly from the 3d CAD model. The software used for converting 3d CAD models to machine code, also called G-code, is known as computer-aided manufacturing software, abbreviated as CAM.

By now, CNC rapid prototyping has become a widely adopted method. It is highly feasible and versatile for a complex and extensive range of product sizes. Various industries, such as automotive, aerospace, healthcare, defense, electronics, etc., use CNC processes for rapid prototyping or short-run production jobs.

Meanwhile, metal and plastic CNC rapid prototyping is fully capable of including threaded/undercut features. It is particularly suitable for prototypes that require tight tolerances, controlled sizes, and a better surface finish. Machined parts are ready to use as processed or surface finish can be further enhanced by secondary processes such as polishing, painting, bead blasting, and plating.

The CNC rapid prototyping fast turnaround time helps experts to validate all the parameters and design fundamentals. For instance, CNC machining helps assess the form, fit, and function of injection molded parts without investing in mold tooling.

CNC Machining Service

CNC Prototyping Shop is a CNC manufacturing and sheet metal fabrication company, including CNC machining services, CNC milling services, CNC turning services, laser cutting services, and stamping services.

CNC Prototyping Shop offers professional CNC machining and rapid prototyping service for making a wide array of product parts. Our excellent quality control systems ensure that all our deliveries are speedy and standard for every manufacturing size in both low-volume and high-volume productions.

Our engineers will help you to find the solution that fits your time, and budget to market, Please contact us today for a quote.