In the world of manufacturing, precision and accuracy are essential elements for producing high-quality products. To achieve this, there are two main approaches to fabricating parts: CNC (computer numerical control) machining and traditional manual machining. In this article, we’ll explore the similarities and differences between these two processes, and discuss the pros and cons of each method.

CNC Machining

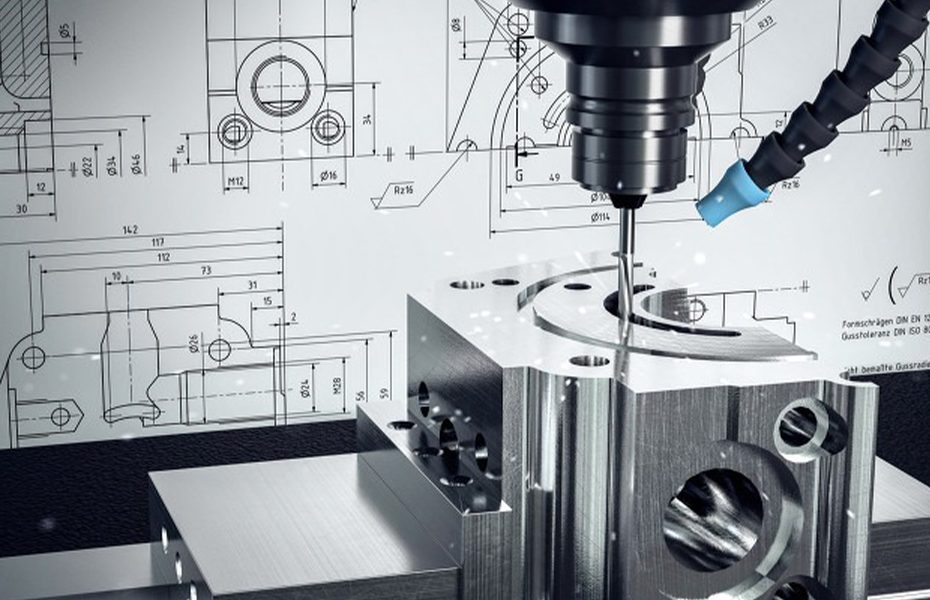

CNC machining is a computer-controlled process that automates the production of parts. The process begins with a computer-aided design (CAD) file, which is used to guide cutting tools to fabricate the desired part. The result is a highly repeatable and accurate process that can produce parts with tight tolerances and complex shapes.

Pros of CNC Machining:

- Precision: CNC machining is capable of producing highly accurate parts with tight tolerances, making it ideal for precision components such as medical devices, aerospace parts, and electronics components.

- Repeatability: CNC machining is highly repeatable, ensuring that each part produced is exactly the same as the last.

- Speed: CNC machining is much faster than manual machining, allowing manufacturers to produce high volumes of parts quickly and efficiently.

Cons of CNC Machining:

- Cost: CNC machining can be expensive to purchase and maintain, and the cost of programming and setting up the machine can be substantial.

- Complexity: CNC machining can be complex to operate and requires skilled machinists to program and maintain the machine.

Traditional Manual Machining

Traditional manual machining is the conventional method of fabricating parts using hand tools and machines such as lathes, mills, and drill presses. The process requires a skilled machinist who can use their knowledge and experience to produce parts with a high degree of accuracy and precision.

Pros of Traditional Manual Machining:

- Creativity: Traditional manual machining allows for more creative freedom and versatility in the production process, allowing machinists to make changes on the fly based on their experience and intuition.

- Flexibility: Traditional manual machining can be used to fabricate a wide range of parts, from simple to complex.

- Cost: Traditional manual machining is a low-cost option for small production runs or one-off projects.

Cons of Traditional Manual Machining:

- Speed: Traditional manual machining is much slower than CNC machining, making it unsuitable for mass production runs.

- Accuracy: The accuracy of traditional manual machining depends heavily on the skill of the machinist, which can lead to inconsistencies in the final product.

Both CNC machining and traditional manual machining have their own unique advantages and disadvantages. CNC machining is ideal for high-volume, precision parts, while traditional manual machining is best suited for small production runs and one-off projects that require creative freedom and flexibility. Ultimately, the choice between CNC and traditional manual machining will depend on the specific requirements of your project, including production volume, lead time, part complexity, and budget.

At DFM Rapid, our passion for precision drives everything we do in our CNC machining services. From aerospace to consumer goods, we have the knowledge and experience to handle a wide range of projects with exceptional accuracy and efficiency. Let us put our expertise to work for you – contact us today to learn more about how we can help you achieve your goals.