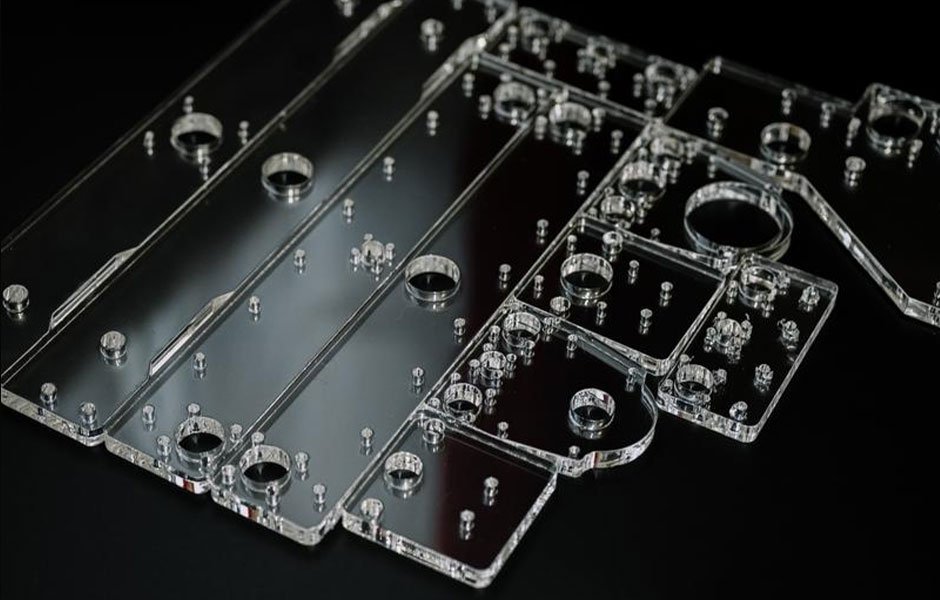

Acrylic CNC service is a complex process. However, CNC machining permits greater accuracy and efficiency when forming products from acrylic. This accuracy means less material waste, allowing you to limit the overall cost of a project.

Acrylic is just one of the most pre-owned clear plastic in CNC systems. This material uses considerable benefits over various other products like polycarbonate and also glass.

CNC acrylic machining is among the most noticeable processes for acrylic production. Many sectors make use of acrylic components. As a result, it ends up being essential to look into its manufacturing processes.

What is Acrylic?

Acrylic is a rigid and transparent thermoplastic material. It is also referred to as Polymethyl methacrylate (PMMA). Many industries make use of acrylic as a replacement for glass since it is shatterproof. It is a colorless and clear polymer that can come in different forms. For example, it comes as small granules, pellets, or sheets.

Machinist then uses different thermoplastic processes for acrylic CNC cutting. Such processes include compression molding, extrusion, and injection molding.

Some manufacturers use cell casting for their acrylic CNC design. Acrylic has a very high molecular mass, making it a tough material. It is also 100% recyclable.

Why use CNC Machining to cut acrylic?

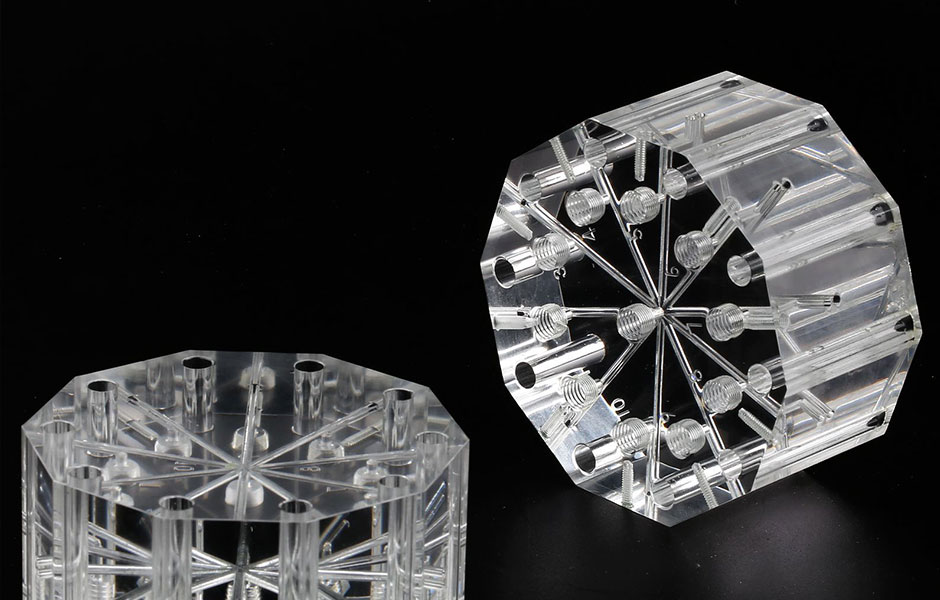

Professionals use CNC machining to shape acrylic for a variety of industrial uses. While it allows for flexible use, acrylic materials frequently break down when compressed or stretched. This means that caution is required when shaping or cutting it. CNC machining is the best tool for acrylic because it works quickly and with precision.

Acrylic Has Many Uses

Acrylic is a desirable material because you can use it in many different ways. It is commonly used in the optical and vehicle industries. Before acrylic can become a particular product, you must cut it to the proper shape. This is where problems occur because of the material’s aforementioned delicate side. Fortunately, CNC machining can handle acrylic easily since it cuts quickly and accurately. You can input the parameters into the machine to create the acrylic shapes that you need.

Less Material Is Wasted With CNC Acrylic

Since the CNC machining process offers great precision, there is very little material wasted. When cutting acrylic with CNC machining equipment, there are fewer stages than when you use other types of cutting gear. This saves time. The process utilizes a computer program that makes cutting stable. Keep in mind that the tool cuts with the same speed and consistency every time, which is different than conventional machining. When using a conventional machine, an operator is in charge of guiding the machine and more likely to cause errors.

What Are the Specifics of Acrylic Material Machining?

- Feed-rates

After fixing the acrylic in place, we can proceed to machine the acrylic blank. We subject most acrylic blanks to milling. The machining process of acrylic is similar to machining polycarbonate. The RPM varies between 15,000 to 18,000 RPM. We proceed by using a stable yet aggressive feed rate. This is ideal to prevent the tool from spending too much time on the workpiece and creating heat through friction. If its feed rate is too low, chips may fall back into the part and spoil the final surface finish and accuracy.

- Cutting tools

We use special acrylic cutting bits that have flutes. These ensure optimum chip removal and accuracy. Moreover, we have to ensure the drill tip angle is less than that of a standard drill when drilling acrylic. Therefore, when the norm is 120 degrees, we instead use 60 degrees. This also helps in better chip removal. Do not worry if we do not achieve an optically clear surface after this operation. The extra operations to carry out afterward aid to promote better clarity and quality finish.

- Coolants

We strive to keep the temperature to a minimum in any CNC acrylic machining process. Cooling helps in chip removal as well as lowers the starting temperature.

CNC Acrylic Engraving

Engraving slightly varies from acrylic machining. We achieve it through milling with a different cutter. We mainly use it when working on aesthetic projects and adverts. Modern CNC methods allow us to engrave even the most complex of designs onto plastic sheets. We can then fill the resulting groove with paint to make it more visible.

Postprocessing CNC Machining Acrylic

Post-processing involves the use of polishing tools in improving surface quality. There are also chemical polishing methods that involve the use of a special gas to melt the outer acrylic layer.

Applications for CNC machining acrylic parts

The acrylic components are trendy because of their worldwide use. Recently acrylic pieces were extensively used to make canopies, gun turrets, windshields, and many more products.

Some of the commercial applications of acrylic components are as follows:

Glass alternative

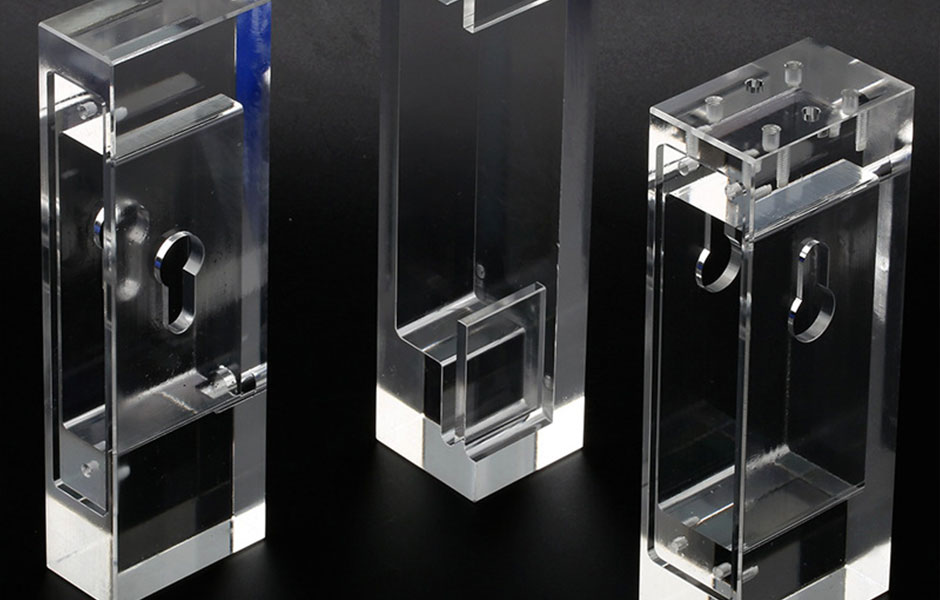

In manufacturing, CNC machining acrylic is used as a glass alternative. Acrylic offers more benefits than glass because of being a more rigid material. Glass cannot be machined as easily as acrylics. Acrylics can manufacture products that require a high level of optical clarity and much more complex geometry. Moreover, CNC machining acrylic components are two times lighter and 30 times stronger than glass, thus increasing the durability of products. Acrylic components are also less expensive than glass.

Medical and dental

CNC acrylic pieces have various applications in the medical industry, and the CNC machining medical components maintain the highest quality because of the tight tolerance and CNC router tooling. Electronic enclosures, implants, surgical instruments, and orthotics are some quality outcome parts. Acrylic is easy-to-clean and pure material. So, they are beneficial in manufacturing devices, cabinets, and incubators in various medical centers. Moreover, they are highly used in dentistry. These are the best choices for dental cavities and fillings. This choice is because they are highly compatible with biologics.

Consumer Goods

The CNC machining of acrylic components shows various applications in consumer goods. These are used to produce different consumer electronics such as smartphones, laptops, and multiple products. They also make many automotive parts, pipe components, and gear bearings.

CNC Machining Service

If you need economical and high-quality CNC acrylic machining services then CNC Prototyping Shop should be your first choice. We will also provide services in developing custom parts according to our client’s requirements.

CNC Prototyping Shop is a CNC manufacturing and sheet metal fabrication company, including CNC machining services, CNC milling services, CNC turning services, laser cutting services, and stamping services.

CNC Prototyping Shop offers professional CNC machining and rapid prototyping service for making a wide array of product parts. Our excellent quality control systems ensure that all our deliveries are speedy and standard for every manufacturing size in both low-volume and high-volume productions.

Our engineers will help you to find the solution that fits your time, and budget to market, Please contact us today for a quote.