Customers turning to us often ask for CNC machining services when looking to create metal parts or plastic parts with intricate shapes. While using this wide term is common and refers to the exact manufacturing method that is not necessary, CNC machining entails two different methods.

They are milling and turning. Both are CNC machining methods but they are not the same.

When your unique project demands high quality, precision, scalability, and a quick turnaround, CNC machining may be the best solution. CNC machining is a manufacturing process guided by computer numerical control and highly skilled machinists. Several methods utilize the CNC machining process, including CNC milling and CNC turning. Choosing between CNC milling and turning largely depends on your project’s specifications, as each process has its advantages.

CNC Milling

Computer Numerical Control Milling is generally a metal manufacturing process; however, plastics can also be milled. CNC Milling uses a computer to control a cutting tool. This cutting tool then cuts material from a workpiece to produce the desired shape/model.

The cutting tool is a major working component of the CNC Mill and can move in three or more axis. Usually, the workpiece is kept stationary, however, modern CNC Mills can rock or turn the workpiece for better cutting angles. This feature also accounts for a speedy process as the machinist does not need to reorient the workpiece whenever a complex design is being milled.

CNC Milling is a rather simple process which is why it is the most widely used production process in the metal industry. From prototypes to final designs, everything is usually done in a CNC Mill.

Advantages of CNC Milling

CNC mills offer numerous advantages to manufacturers and prototype companies. Unlike lathes, mills are versatile machines capable of creating a range of different shapes. Furthermore, a variety of cutting tools can be used to serve different operations such as roughing and end-milling.

Although they are manufacturing machines in their own right, mills are also useful for post-machining. For example, they can be used to add details to turned, molded, or 3D-printed parts.

CNC milling is also fast, repeatable, and inexpensive in low volumes — partly because it does not require tooling. It is therefore found among manufacturing services and rapid prototyping services.

Here are some of the CNC milling methods:

Plain Milling

-Plain milling is also known as surface milling. In this milling process, a cutting tool gets used to remove the material along the surface of the workpiece. The rotation axis is parallel to the workpiece.

Face Milling

-Face milling uses a rotational axis that is perpendicular to the material’s surface. The cutting tool is faced down against the workpiece to remove the material.

Form Milling

-Form milling makes non-flat cuts like contours, curves, and more. Each type of curve requires a specific cutting tool to create a precise cut.

Angular Milling

-In this milling method, the cutting tool’s rotary axis is at an angle to the workpiece surface to manufacture angular cuts as specified in the design.

CNC Turning

CNC turning is a form of CNC machining that machinists use to make rounded, cylindrical, and conical parts. Although it is less versatile than CNC milling, it is one of the most popular CNC machining services and rapid prototyping services.

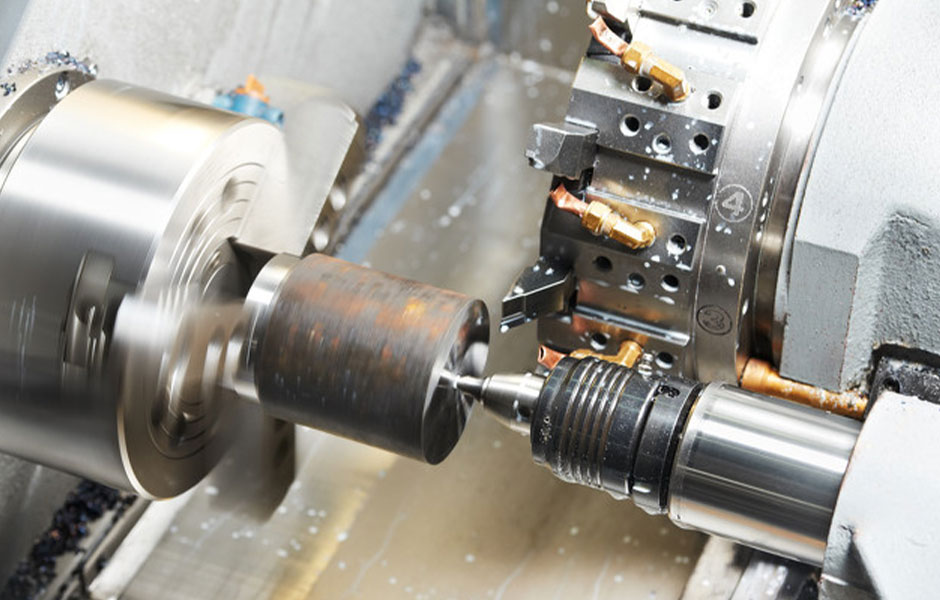

Machines that carry out CNC turning are called CNC lathes or CNC turning centers. They are different from CNC mills in that they rapidly rotate the workpiece in a chuck but do not rotate the cutting tool. The cutting tool, affixed to a turret, moves towards the spinning workpiece under computer instructions and removes material where necessary.

A CNC lathe can cut the outside of the workpiece or bore through the inside to create tubular CNC machined parts.

The turret of the machine may have multiple cutting tools that can be individually engaged as required.

Advantages of CNC Turning

The biggest advantage of CNC turning is its ability to create round profiles. It is much more difficult to achieve perfect roundness using other CNC machining services like CNC milling or CNC routing.

CNC turning is also highly accurate, which makes it a valuable technology for boring holes of precise dimensions with set tolerances.

CNC milling and CNC turning can be combined to reap the benefits of both processes. In most cases, CNC turning takes place first, allowing the machinist to mill further (asymmetrical) details on the part.

Various turning operations get utilized to cut different shapes for the workpiece:

Tapered-turning

-In taper turning, a canonical surface gets created by the incremental reductions from one part to another.

Hard turning

-Hard turning is the process of turning the workpiece harder than 45 HRC. Hard turning is ideal as the replacement for grinding operations.

Boring

-Boring is the process of widening the drilled hole in the workpiece by subtracting material using a single-point cutting bit. It gets used to cut holes of precise dimensions and tapered holes.

Drilling

-Drilling is the process of creating a round hole in the workpiece to remove the material from it. The drilling gets done by firmly holding the standard drill press in the turret of the lathe.

Example parts made with CNC milling include:

- Fittings: Milled fittings connect two or more parts together

- Enclosures and housings: Electrical devices and other products can use custom-milled enclosures to protect internal components

- Brackets: Milled brackets can contain custom threads and holes and may be more complex than sheet metal brackets

- Gears: CNC milling can produce straight and spiral gears for mechanical devices

- Mold tooling: Milled tooling, made of steel or aluminum, allows for rapid prototyping of molded parts

- Engine parts: Automotive engineers use CNC milling for engine blocks and other parts

- Medical devices: CNC mills can produce implants, surgical instruments, and other medical devices

- Water pumps: Multi-axis mills can create reliable impellers for hydraulic equipment

- Forming punches: CNC mills can create other manufacturing equipment, such as forming punches for sheet metal fabrication

Example parts made with CNC turning include:

- Rollers: CNC lathes can fabricate rollers with tight tolerances for industrial use

- Ball joints: CNC turning is ideal for rounded connective devices like ball joints

- Nuts and bolts: The accuracy of turning makes it suitable for tolerance-critical items like nuts and bolts

- Shafts: Shafts with rounded profiles are highly suited to CNC turning

- Flanges: CNC-turned flanges can strengthen beams and pipes

- Nozzles: Nozzles are typically cylindrical or conical with hollow insides, making them suitable for CNC turning

- Turbines: CNC turning can produce round turbine blades for the energy industry

- Firearms: A CNC lathe can produce the tubular shape required for a firearm barrel

Conclusion

While these two are often packaged under the same term – CNC machining – they are not the same. Still, they can complement each other beautifully to produce parts with high precision.

For example, turning a shaft may later need adding features with a CNC mill.

CNC Machining Service

CNC Prototyping Shop is a CNC manufacturing and sheet metal fabrication company, including CNC machining services, CNC milling services, CNC turning services, laser cutting services, and stamping services.

CNC Prototyping Shop offers professional CNC machining and rapid prototyping service for making a wide array of product parts. Our excellent quality control systems ensure that all our deliveries are speedy and standard for every manufacturing size in both low-volume and high-volume productions.

Our engineers will help you to find the solution that fits your time, and budget to market, Please contact us today for a quote.