Anodizing is one kind of surface finish to protect your custom metal parts against corrosion, resists scratching, and enhances aesthetic quality, it is one of the most durable surface finishes available for metal parts. Aluminum Anodizing is widely used in many different industries.

What is Anodizing Process?

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. Aluminum is ideally suited to anodizing, although other nonferrous metals, such as magnesium and titanium, also can be anodized.

The anodic oxide structure originates from the aluminum substrate and is composed entirely of aluminum oxide. This aluminum oxide is not applied to the surface like paint or plating but is fully integrated with the underlying aluminum substrate, so it cannot chip or peel. It has a highly ordered, porous structure that allows for secondary processes such as coloring and sealing.

Anodizing is accomplished by immersing the aluminum in an acid electrolyte bath and passing an electric current through the medium. A cathode is mounted to the inside of the anodizing tank; the aluminum acts as an anode so that oxygen ions are released from the electrolyte to combine with the aluminum atoms at the surface of the part being anodized. Anodizing is, therefore, a matter of highly controlled oxidation the enhancement of a naturally occurring phenomenon.

How the Process of Anodizing Aluminum Works

In order to properly anodize aluminum parts, the surface must first be cleaned and rinsed before getting placed into a bath of an electrolytic solution, primarily either sulfuric or chromic acid. This provides an electrically conductive coating that contains a number of positive and negative ions.

So how does this process really work? Well, once the anodizing process is underway, a positive electric charge is sent through the aluminum, while a negative charge is applied to plates in the electrolyte. Basically, the electric current forces the positive ions to attract to the negatively charged plates while the negative ions are attracted to the aluminum part, which is the positive anode.

From here, the electrochemical reaction forces pores to open up on the surface of the aluminum so that the positive ions can escape. In a uniformly geometric pattern, these pores dig down into the substrate of the part. The combination of the aluminum surface and negatively charged ions create a barrier layer, which is known in the anodizing aluminum process as the surface layer that makes parts resistant to corrosion.

There are currently four different variations of the anodizing aluminum process, each of which offers distinct advantages over the others:

Anodized Type I: This is the most basic type, using chromic acid to produce a thin and ductile anodized layer on an aluminum part.

Anodized Type II: Instead of using chromic acid, Type II utilizes sulfuric acid in order to produce a thicker anodized layer on the part, making it more suitable for coloration.

Anodized Type III: Similarly to Type II, this method also uses sulfuric acid, but produces a thicker anodized layer that is also suitable for coloration. It’s also commonly known as “hard anodizing”.

Chemical Film / Alodine: This method entails coating the part with Alodine to produce results that are comparable to anodization.

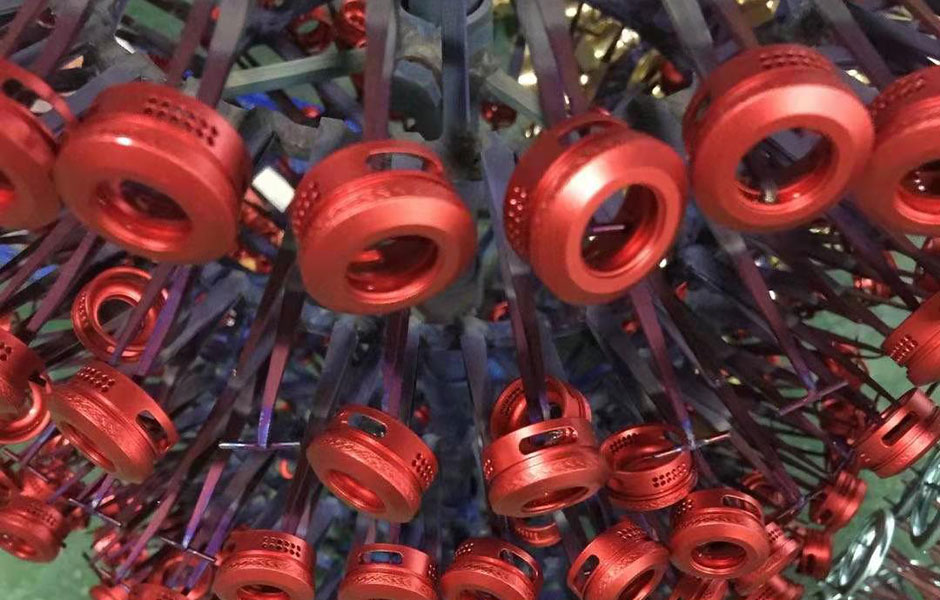

Anodizing aluminum parts also presents an array of options when it comes to adding color. The coloration process works by injecting a pigment into the empty pores of the part. Once the colored pigment reaches the surface, it’s sealed off to preserve the selected color. This creates a visual effect that won’t fade away and can’t be scratched off, keeping the appearance of your parts in premier shape.

Aluminum Anodizing Service for Your Custom Metal Parts

We are able to offer advice on many different finishing services including aluminum anodizing service, painting, silk printing, etc for your rapid prototyping and low-volume manufacturing needs. Our engineers will help you to find the solution that fits your time, and budget to market, Please contact us today for a quote.