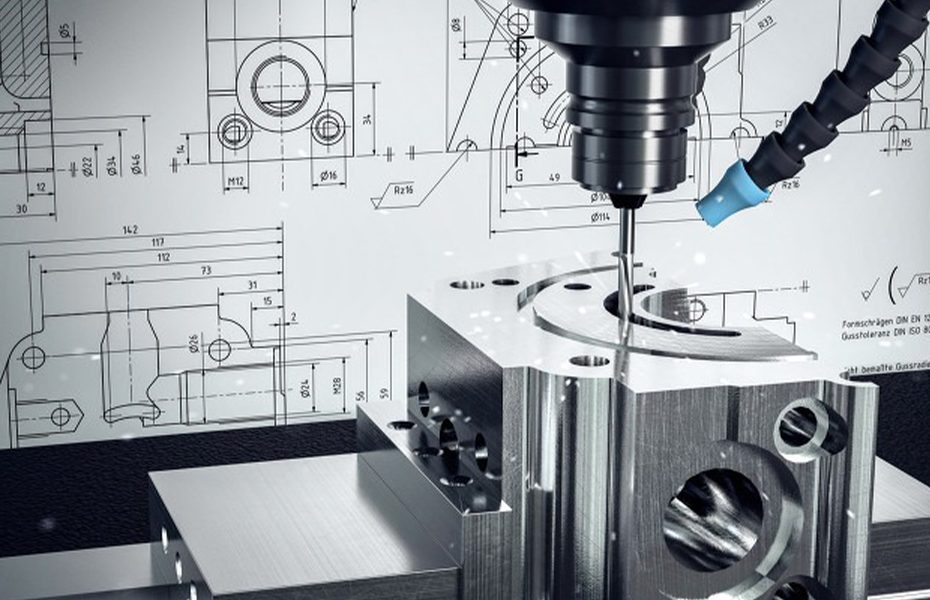

CNC milling is a manufacturing process that uses a cutting tool mounted on a rotating spindle to selectively remove material from a block of raw substrate. The workpiece is rigidly mounted to a table, and this table moves or rotates on different planes so the tool can work at many angles.

This process can be carried out on a vast array of materials including (but not limited to) metals, plastics, rubber/foam, wood, plastic and more. CNC mills come in a variety of sizes and axis configurations, and can be customized to meet specific production requirements (cutting envelope, tool pockets, machining speeds, etc.)

Sophisticated CNC milling machines can have 5 or more axes of independent motion to make more complex shapes or to avoid having to move the workpiece to a separate machine.

The CNC mill is typically programmed using CAM software, but they can also work effectively through manual G&M code entry as well as interactive programming systems that are offered by a growing number of machine tool providers. The code that is generated is then used to give commands to the machine such as when/where/how to move and operate (i.e. change stock position, turn cutting head at a specific rate, move along a given path, etc.) Depending on the complexity of a given part, a CNC Mill program can consist of thousands (even millions) of lines of code.

How Does CNC Milling Work?

CNC milling is one of the most innovative manufacturing technologies to date. A cutting tool spins at high speeds in a central spindle and executes movement functions according to a preprogrammed set of code. Common cutting tools included drills, taps, end mills, and more. At the same time, stock material (which has been fixed in place using various work-holding methods) will also move, spin and rotate to expose different machining surfaces. Because all operations are controlled by the computer,

CNC mills can produce large production with speed, precision and accuracy, all while requiring minimal operator intervention. Most modern CNC milling machines can automatically switch between different

cutting tools via an automatic tool changer, and many are equipped with part loaders and tool/stock probes to increase the degree of automation.

Common milling operations include: drilling, tapping, countersinking, milling profiles, contours, slots and pockets, etching/engraving, edge breaking (radius/chamfer), facing, and many more.

Advantages and Limitations of CNC Milling

CNC milling, like other CNC machining methods, offers numerous advantages. Some of the most notable include its precision, its replicability, and its low labor costs.

However, milling does have a handful of drawbacks. One is the high upfront cost of the machinery, as product teams must either invest in expensive CNC milling machines up-front or outsource services to a trusted manufacturer. It also requires specialized training to perform successfully, complicating the process should teams choose to invest in their own machinery.